What about moisture in the form of water vapor? Water vapor moisture is produced both outside (humidity) and in- side (steam from cooking and cleaning). e second law of thermo- dynamics says that stuff moves from areas of greater concentration and higher energy to areas of less concentration and lower energy. With regard to vapor, air carrying the moisture (vapor) always moves from high pressure toward low pressure, and water moves from wet toward dry and from warm toward cool. When water vapor hits a cool surface, it condenses and changes from vapor to a liquid. If this is within the wall assembly, that becomes a problem, leading to mold growth and issues with rotting assemblies and poor indoor air quality. Vapor barriers (like vinyl, polyethylene or the asphalt-coated Kraft paper face of our insulation batts) can either help to prevent this from happening, or can actually contribute to the problem, depending on the climate.

So you may or may not need or want a vapor barrier. The goal is to control or stop condensation. ere are two ways to do this. One is to stop the warm moist air from coming into contact with the cold surfaces. e other is to warm the surfaces so that they are too warm for condensation to occur.

In the past, we primarily used the idea of stopping the moisture using vapor barriers in our wall assemblies. is is the concept behind the plastic vapor barrier covering the studs. Getting a perfect plastic vapor barrier installation is very hard and detailed work, and there have been far too many instances where small overlooked holes have caused major problems, so now there is another option. With the advent of rigid foam insulation board, we can now warm the wall surfaces to prevent condensation. And this provides the additional benefits of increasing the total insulation of the wall assembly and reducing thermal bridging.

When we do use a vapor barrier, where we place it is determined by which direction the wall will dry towards. Remember, our goal is to stop the water vapor from finding a cold surface and condensing while still allowing the wall to dry in the other direction. Strange as it might seem, northern homes dry out while southern homes dry in.

For example, if your home is in a very humid, cooling-dominated climate like Dallas, Texas, (or in a mixed-humid climate like in the Midwest), the direction of water vapor drive is from the warm, humid outside air toward the dry, cool air inside of the air conditioned home. As moist air comes in contact with the backside of cool conditioned wall surfaces, condensation and related problems can occur. is is especially true if the owners have kept the house at a temperature below the outdoor dew point temperature. If we had placed the vapor barrier on the inside of an exterior wall, it would have exacerbated the problem by halting the ability of the water vapor to dry to the inside. Many a builder . has removed vinyl wallpaper and found the drywall under it covered with mold and not understood the source of the excess moisture. So the right place for the well-sealed vapor barrier/vapor retarder is to the outside of the wall assembly, allowing the moisture to dry to the inside.

Now, let’s consider a home in a heating-dominated climate like Minneapolis or Toronto. The warm/humid side of the house walls most of the year is the inside, and the cool/dry air is on the outside of the house. In this climate, the water vapor is driven from the inside toward the outside through the building assemblies in long winter. As this warm, humid air reaches the backside of the cold exterior sheathing, it again causes a condensation problem. e place to put the vapor barrier would be on the inside of the wall assembly.

Except for extremely cold climates, we can skip the vapor barrier entirely and opt for installing the exterior foam sheathing, which keeps the wall assemblies warm enough to prevent condensation. We call this putting a coozie on your house. e thickness of the foam sheathing required depends on your climate zone. In the mild winter areas, one-half inch to one inch will do the trick. In mixed climate zones (fairly equal heating and cooling seasons), you should use an inch to an inch and one-half of rigid foam on the outside of the wall. In areas with very cold winters, you will need to install one and one-half-inch or two inches of rigid foam board to ensure that you keep the wall cavity warm enough to be trouble free. If you check with your local building code official, they can look up what is recommended in their code books.

You can paint the inside wall with two coats of latex paint and that acts as an interior wall vapor retarder, slowing the rate of vapor diffusion. When combined with the exterior foam, this is an excellent system that works very well in any climate zone.36 is has been called “the perfect wall” by the building science community.37 It also works as the perfect floor when rotated ninety degrees and the perfect roof when sloped properly. It controls water vapor condensation, temperature and thermal bridging and allows drying to the inside.

In the following drawings you can see the direction of water vapor ow and therefore the direction of drying that occurs in heating- versus cooling-dominated climates. e fact that the way a wall dries is not the same in all parts of our country has led to many poor decisions and confusion about where to place the vapor barrier in a new home. e diagrams also illustrate how the vapor barrier reduces the moisture load on the wall assembly, thus protecting it. e rule of thumb is to place the vapor barrier on the side of your wall that is more humid and warmer for the majority of the year. In hot, dry climates, walls that have no vapor barriers at all, o en called breathable walls, are a good option. Also, avoid using moisture-stopping drywall products, as are commonly used around bathtubs and showers, in areas where direct water contact is not an issue.

Followers.

Vapor Barriers - Exterior Wall Assembly

Saturday, October 28, 2017Publicadas por Edd a la/s 12:55 PM 13 comentarios

Flashings - Exterior Wall Assembly

There’s an old saying that fits this topic very well: the devil is in the details. at’s because it’s how we ash windows, doors, porches, chimneys and other key areas of the exterior walls and roof that will keep the water out of your home. Flashings are one of the most important and overlooked components of the building envelope that make or break long-term resistance to damage. Make certain that your framers and roofers are using the right materials for the job and installing them in the proper fashion. is is not the place to cut money from your budget! Flashings of all sorts are manufactured to t every joint and intersection of your exterior building envelope, to cover all the different angles, seams, gaps and penetrations. It’s not just the materials; even more importantly, how they are installed keeps the water running downhill.

With windows, the process begins with a sill pan or a layer of waterproof material covering the bottom of the rough opening that the window will be installed in. is material should be turned up at the corners at least six inches on the inside of the studs and then extend out on top of (not under) the house wrap below the open- ing. The house wrap has a wrap cut above the window. The window is then installed, and the sides are flashed with an adhesive tape, followed by a layer of flashing tape across the top of the window flange. The flap of house wrap is then brought down over the top flange, and it is taped in place with flashing tape. The bottom flange of the window is not flashed. is will allow any water that does get into the opening to drain out and ow down the waterproof drainage plane of the house and out the weep holes or screed at the bottom of the wall. By the way, the order that these flashings are installed, from the bottom up, is critical. For curved windows and doors there are flexible flashing tapes on the market now that work very well.

The process for porches and decks is much the same. e drain- age plane material is fully installed before the ledger board is put in place. A er attaching the ledger board, the drainage plane is cut above the ledger board to which the joists will be attached. A ash- ing material like metal or flexible waterproofing is attached to the sheathing, and wrapped around the front of the ledger board. e drainage plane is then turned down over this flashing and taped in place. You can obtain detailed drawings showing exactly how these openings need to be flashed on the websites of the house wrap or window manufacturer for your project.

The addition of an insulated sheathing to the wall assembly re- duces thermal bridging. Or you can replace the rainscreen assembly that we just described with an insulated sheathing panel system that is taped at all seams (with a 50-year warranty). These types of water management systems are always employed behind masonry or stucco walls (because water penetrates those materials so rapidly) and behind wood walls, too, in rainy or marine climates.

Publicadas por Edd a la/s 12:45 PM 6 comentarios

Etiquetas: Walls

Radiant Barrier - Exterior Wall Assembly

A radiant barrier is the foil-faced roof decking (with the foil facing the attic side) that stops radiant heat gain through a vented roof assembly in hot climates. is is usually one of the first upgrades for existing construction if your roof design allows good access for installation, along with improving the insulation in the attic if needed. Note that radiant barriers require an open, ventilated air space on the side facing the house, so they should not be installed in a sealed attic, as they simply don’t work when foam insulation is in contact with them.

If you live in a cooling-dominated climate, you should also strongly consider using aluminum foil faced radiant barrier roof decking material with an emissivity of 0.05 or less26 to keep your attic cooler in the summer. is will at least prevent much of the radiant heat gain through the roof assembly. is results in helping to take some of the heat load o your air conditioner and ducts during hot weather.

Publicadas por Edd a la/s 12:31 PM 8 comentarios

Etiquetas: Walls

Ice Dammin - Exterior Wall Assembly

Ice dams are a source of tens of millions of dollars in home damages each year. Homeowners have tried heat tapes at the edge of the roof, rakes, more ventilation in the attic and a million other ideas to stop this threat, but with limited success. e build- ing science community has been able to determine how and why ice dams occur, and this has led to a successful strategy to stop them. They found that the problem isn’t at the eave—that’s just where it becomes evident and does its damage. e ice dam itself is just a symptom of the real problem.

Preventing ice dams is all about creating an effective air and insulation barrier at the ceiling of the house. An ice dam starts when heat is allowed to rise from the ceiling of the house at what building science calls thermal bypasses (explained below) and melts the underside of the snow pack on the roof. is meltwater runs down the warm roof as liquid at just above freezing. It stays liquid until it reaches the exposed eaves of the house, and there the temperature of the roof deck suddenly drops because the deck is fully exposed on the bottom side to the cold outside air. e meltwater ash freezes at the eave, and the ice dam begins to form. As more water melts and runs down the roof, it builds up a small lake behind the ice dam and backs up under the shingles to run down the walls of the home. If the snow pack stays frozen, there can be no ice dam. e solution is to correct the cause, not to deal with the ice dam itself. In other words, stop the heat from rising at the ceiling of the house and the snow pack will stay frozen and no ice dam will be able to form in the first place.

This requires us to seal all thermal bypasses and insulation defects in the ceiling of the home. A thermal bypass is a place where the insulation and ceiling air barrier have holes in one or both system (remember: “continuous and contiguous”). These are places like open utility chases for plumbing, wiring and ducts, dropped ceilings and other irregularities that provide opportunities for breaks in the drywall air barrier and insulation at the ceiling. These openings will act as a chimney for warm air to escape into the attic where they rise and warm the roof deck.

All thermal bypasses must be sealed airtight with rigid materials like plywood or foam board, then air sealed with caulk or foam sealant and then covered thoroughly with insulation. is is a job best done by the framing crew during the initial framing of the home. Subcontractors who later penetrate these air barriers must be held responsible for resealing them once they have installed the plumbing, wires or ductwork that runs through them. Any areas of missing insulation must be fully insulated.

Recessed can lights are notorious thermal bypasses. They are not only ventilated to allow warm house air to pass through, but they generate their own heat when the lights are on. e energy

star Certified Homes Program has an excellent list called theermal Bypass Checklist24 showing everything that must be sealed for a home to be certified.

The best solution in new construction is to seal everything on thermal Bypass Checklist and to use only recessed light fixtures that are airtight rated and also rated for insulation coverage. These lights are o en called AT/IC-rated recessed fixtures. They should meet ASTM E-28325 and be labeled as such.

If you can’t replace the old leaky can lights in your existing home, consider a code-approved option. Build a sealed box out of drywall that leaves a clearance around the fixture as specified by the manufacturer. Cover the cans with the drywall boxes and seal the boxes down to the ceiling drywall. is will stop the air from rising through the cans and heating the roof deck and starting the process that leads to ice dams.

Publicadas por Edd a la/s 12:28 PM 9 comentarios

Air Barriers - Exterior Wall Assembly

Also, since insulation is a material full of air pockets, it is important to stop air ow through that material. For insulation to be effective, it must be encased by an air barrier. Air barriers function to keep air from freely owing through insulation, allowing it

to achieve the thermal performance (R-value) at which it was rated. To be effective, insulation and air barriers should be both continuous and contiguous, meaning that every exterior building assembly is insulated and encased by an air barrier. Research has proven that installing insulation without an effective air barrier results in a huge reduction in the effectiveness of the insulation and high bills with poor comfort.

Wherever the insulation is installed, there must be an air barrier in contact with the insulation on all six sides, leaving no insulation exposed; this prevents convection currents. e wall studs, along with the top and bottom plates, close up four sides. e exterior sheathing encloses the outside of the cavity, and drywall normally encloses the inside, but not without exceptions.

These exceptions are because there are areas of the thermal envelope that may be insulated but o en do not have drywall installed on the inside of the cavity. is includes replace and HVAC chases and behind bathtubs when these features are located on an exterior wall. is can also include a stairwell on an exterior wall, even if part of the area under the stairs is a closet. Usually the under-stair closet ceiling slopes down to a point such that the bottom few steps of the stair would create a ceiling height too low to be usable. These bottom few steps, if on an exterior wall, will usually not have that area of the wall enclosed with drywall. In these areas, it is necessary to install some other type of air barrier to encase the insulation on the inside of the wall assembly.

Note that an air barrier is shown installed on the inside and out- side of the wall common with the attic space, o en called a knee- wall or pony wall. These are vertical walls that separate a room from an attic space. Typically, builders do not install an air barrier on the attic side of these walls. They just stuff some batts into the cavities and call it good enough. They also don’t place air blocking in the big holes under the knee walls where the ceiling framing runs. is leaves dozens of big holes (16 inches by 8 inches) open so that out- side attic air easily blows between the uninsulated floors and ceilings. In cold climates, the result is o en frozen pipes between the floors of the home where you would think that cold air shouldn’t be able to go. Very o en rooms over garages are uncomfortable be- cause they su er from both of these problems. These areas, even if insulated, are large holes in your thermal envelope when not sealed by some type of air barrier.

The exception to the air barrier installation requirement is if you are installing blown insulation on the attic floor. For blown-in insulation in the attic floor, significantly higher R-values are typically required by building codes to achieve the desired resistance to heat needed here. Since the insulation is not installed vertically, it is not as susceptible to convection loops and for this reason doesn’t need to be encased on the sixth side. e depth markers that are commonly seen in this type of installation ensure the depth of the insulation achieves its stated R-value.

A common hole in attic insulation occurs at the location of an attic scuttle hole or attic stair. Any attic access that penetrates the thermal envelope should be well sealed with weather stripping, with multiple layers of rigid board insulation applied to the attic side of the board cover, or by installing an insulated stair unit.

Air barriers should be sealed at all penetrations. On the exterior side of the insulation, the house wrap or rigid foam board must have all seams taped. To complete the air barrier, it is necessary to caulk and seal all penetrations in the building envelope. ere can be no exception to this rule. Some of the more common penetrations in wall and roof assemblies include plumbing and mechanical vents, condensation drain pipes, replace chimneys and electrical conduits, fixtures, and outlets. Air infiltration into the building assembly occurs wherever these penetrations are not properly flashed or sealed.

The way to know if you have an effective air barrier is to test the house under pressure and then measure the air infiltration rate. Since 2009 this test, o en called a blower door test, is required by code, but if you do not live in an area that mandates code inspections, you should make sure your builder is aware of the blower door test and that you see the results. e house must be tested and proven to be a very tightly sealed structure by achieving no more than 5 air changes per hour at 50 pascals of pressure (ACH50). is standard will be restricted even further to no more than 3 ACH50 in climate zones 3–8 by the 2015 International Energy Conservation Code (IECC) (advance information June 2014).

Publicadas por Edd a la/s 12:10 PM 10 comentarios

Thermal Barriers - Exterior Wall Assembly

“ Thermal barrier” is a fancy term for insulation. In a high-performance home, insulation should be installed on all exterior surfaces in an unbroken sequence. Any gaps, voids or breaks in the insulation coverage of the entire building assembly can result in heat loss or gain. is is shown in the image below with the use of a thermal imaging camera. In a color photo, heat loss shows up as warm yellow or orange and cool well-insulated areas are blue or black. In this black-and-white rendition, light and bright areas indicate heat loss.

Thermal bridging is the rapid transfer of heat through a build- ing component when that component has less thermal resistance (R-value) than materials surrounding it. Framing materials o er a good example of thermal bridging through the building envelope. Wood has an R-value of a little less than one per inch, so a typical 2 × 4 stud has an R-value of around 3.5. Compared to the surround- ing insulated wall cavities, if perfectly installed to manufacturers’ specifications to achieve R-13 or R-19, that’s quite a difference. So, if you look closely at the image above, the thermal movement through the wood-framing members allows you to see all of the studs and even the roof rafters glowing with the heat they are losing. Thermal bridging can greatly reduce the effective insulation value of a wall, floor or ceiling.

Another place where poorly insulated wood is typically used is for structural headers to displace the vertical loads over windows and doors, as was mentioned previously. is volume of uninsulated wood creates large areas of thermal bridging, significantly reducing the overall thermal performance of the entire wall assembly. As was mentioned earlier, it’s unfortunate that many framing crews are taught to install headers over every window and door, even when they are located in non-load-bearing walls. is usually hap- pens due to a lack of framing detail provided to them by the structural engineer or truss designer. Best practices are to install headers only where they are required structurally, to size them only for the actual load they are to carry and to insulate them. Many insulated structural header products are available on the market, or you can make your own by sandwiching a rigid foam board panel between two layers of wood (or structural wood product) to create a thermal break.

By adding a layer of rigid board insulation on the exterior of our entire wall assembly, we can reduce or eliminate thermal bridging, as this material provides an insulated break between the wood framing and the exterior heat source. By sealing the attic and insulating over the exposed roof rafters, we can reduce or eliminate thermal bridging there using the same approach. We could also

choose to use an alternative building system, like SIPs, ICFs, AAC block or a natural material, which could significantly reduce thermal bridging in the building assemblies.

We recommended raised heel or energy truss de- sign as a remedy for insulation gaps between the top of the wall assembly and the edge of the roof assembly. It is evident from Figure that this home suffers from poor insulation in the so t area, a significant source of heat loss in the winter. These are like holes in the thermal envelope, and so the walls perform as if someone has left a window or door open, putting additional strain on the air conditioner or heater as it attempts to provide comfort under these conditions.

Finally, note the heat loss through the foundation or basement perimeter. is has become a more important issue as we built tighter thermal envelopes, which should enable us to reduce the size of air conditioning and heating systems required to keep them comfortable. However, this heat loss through the foundation assembly can result in raising the heating loads, negating any savings achieved in the main building assembly. In fact, we have seen in- stances in the last couple of years where heat pump system sizing is being determined by these heat losses, driving up heating loads even in cooling-dominated climates with very mild winters. is means that although we did a good job reducing the cooling loads through building science and envelope improvements, we were forced to install a larger HVAC heat pump system to handle the heat loss through the foundation in the few very cold days of winter that occur. is is the best argument for insulated slabs in any location that has any chilly winter days. An insulated slab or basement can reduce the heating load on the home by as much as 25 percent or more depending on your climate and house plan.

Publicadas por Edd a la/s 12:06 PM 15 comentarios

Etiquetas: Walls

Advanced Framing

Optimal Value Engineered (OVE) or Advanced Framing techniques are framing techniques that use less lumber than conventional framing, yet are just as structurally sound. Using 5 to 10 percent less lumber is cheaper and faster because it uses 30 percent fewer framing pieces,21 which equates to a direct reduction in lumber package costs. But, as important, these methods also present one of our best opportunities to improve the thermal performance of the structure.

Remember, thermal performance is one of our primary goals. Because Advanced Framing uses less lumber, this leaves more space in the cavities to allow for higher levels of insulation, resulting in better thermal performance. In fact, Advanced Framing results in a 75 percent improvement in thermal performance22 over standard 2 × 4, 16-inch-on-center framing. e lumber cost savings can add up to enough to cover the additional costs associated with improv- ing the thermal performance, including the cost of adding insulated sheathing to reduce thermal bridging through the wall assembly.

This is definitely a case of “less is more,” in that using less lumber saves trees and uses less money in your budget, with the added bonus of leaving more room for insulation, giving more thermal performance. ink about that because it represents significant improvement in your building performance for minimal additional construction costs and lowers your long-term utility bills. So if you are planning a framed structure, you should make certain that your framing contractor has been trained in and practices the methods discussed here.

Many computer-aided design (CAD) programs can be set to a grid of either 16 inches or 24 inches on center (the distance from the center of one framing member like a wall stud or ceiling joist to the center of the next) to allow for ease of designing to these two basic spacing criteria. Providing these Advanced Framing details in your architectural plan sets can assure that you bene t from those cost savings and performance benefits. Better efficiency, improved comfort, and reduced costs are all achieved in each of the following methods:

Framing 24 Inches on Center: Exterior wall studs, floor joists and roof rafters can be spaced at 24 inches on center (as opposed to the conventional 16 inches on center). Depending on the load bearing on walls, framing lumber may require 2 × 6 studs rather than standard 2 × 4 framing. Note that the total cost (material and labor) for framing with 2×6 studs spaced 24 inches on center is about the same (since 30 percent fewer studs and only a single top plate are

required) and o en less than what it would have cost for 2 × 4 studs spaced 16 inches on center. Because there are fewer studs to cut, there is less waste. is also saves labor for both your electrical and plumbing contractors, who now have to drill fewer penetrations for mechanical runs.

However, with most types of cavity- ll insulation (depending on climate R-value requirements), it may cost more to ll a 2×6 cavity than to ll the same structure framed with 2 × 4s. is is not only due to the increased depth of the studs but also to using less framing materials overall, so it will take more insulation material than it would have for the same depth, regardless. In addition, the added two inches of wall thickness will require extension jambs at all of the windows unless drywall returns are used.

In-line Framing: Aligning the floor, wall and roof framing members directly above one another so the loads are transferred directly downward, requiring no additional structural support, can save considerably on structural engineering and framing costs. With in-line framing for improved load stability, double top plates can be eliminated because the load is distributed evenly through the remaining single top plate. Note that studs that are 24 inches on center are placed in direct alignment with floor joists spaced 24 inches on center and directly below roof trusses spaced 24 inches on center. e structural concept is to align all point loads to carry the weight directly down to the ground.

Headers Sized for Actual Loads: Structural headers are o en over- sized or installed over all window and door openings, regardless of whether or not they are structurally necessary. When the size of the window used is specified in conjunction with in-line framing, headers are not necessary because no studs need to be cut. If walls are not load bearing, no headers are required over window or door openings. Having your structural engineer specify which areas will require headers, as well as the size of each header required, will save both materials and money.

In most cases right-sized headers can be pushed to the outside of the framed wall assembly, allowing for insulation on the inside of each header cavity, which not only improves the overall thermal performance of the wall assembly but also eliminates thermal bridging at the headers. Note that it is possible and now required by code to insulate headers by using foam sheathing as a spacer in place of plywood or oriented strand board (OSB), either between or on one side (preferably the exterior side) of doubled headers. is technique uses scrap foam sheathing to reduce thermal bridging through the wood header.

Two-stud Corners (California Corner) with Drywall Clips: is method of corner framing uses only two studs, saving material and providing space for additional insulation in the corner. To attach drywall in a two-stud corner, drywall clips are fitted onto the edges of the drywall before being attached to wood or steel studs. is eliminates the need for an additional stud in the corner to attach the drywall.

Window and Door Placement: By aligning at least one side of each window and door to an existing wall stud, use of an additional jack stud is not necessary. If the window or door width does not completely ll the cavity and align with the next stud, you can attach the other side to the next stud with a metal hanger. is eliminates the need to frame additional studs to support the load transfer around these penetrations in the wall assemblies.

Interior Partition Walls Intersecting with Exterior Walls (T-walls): Traditional framing addresses T-wall intersections by adding studs at each side of the partition solely for the purpose of providing a surface for attaching drywall. Ladder blocking between the exterior studs behind the partition wall uses two-foot scraps of lumber to provide the same supporting structure and allows for much better wall insulation and reducing thermal bridging. You can use scrap wood for ladder blocking, reducing the additional lumber you need to purchase.

Publicadas por Edd a la/s 11:59 AM 6 comentarios

Etiquetas: Green BuildIng

Structured Plumbing

Thursday, October 26, 2017A greater water savings can be realized by downsizing the diameter of the pipes and reducing the number of runs using the structured plumbing approach. With today’s more water-efficient fixtures and appliances, we no longer need three- quarter-inch runs or even half-inch runs to each outlet. is not only saves on your plumbing materials, it also saves water over the life of the home.

The structured plumbing design uses twig lines that typically extend no further than ten feet from the main trunk, with the exception of large volume fixtures at garden tubs, clothes washers or sinks in a kitchen island that run the water line through a concrete slab. is type of system uses less pipe and can be installed faster, saving money on your base bids. Since water stays hot longer in the larger main trunk line, only the water in the twig lines is lost down the drain when hot water is already in the main loop.

The best strategy for reducing water wasted down the drain waiting for hot water delivery is a structured plumbing system con- trolled by an on-demand pump. is can use a closed hot water circulation loop with a dedicated return line to the water heater or use the cold water line to return water until hot water is delivered to the open fixture.

Even if your home design is plumbed through using a standard plumbing branch and twig run, you can still install an on-demand recirculation pump at the fixture farthest from the water heater. If your plumbing is designed such that you have numerous wet locations in different directions some distance from the water heater, you may need to install multiple demand pumps at the furthest fixture on each run. e pumps are operated by a wireless door- bell button or light switch that is activated only when hot water is needed at that location. Other wet areas along the same line may also have activation switches to run the same pump at the end of the line. e pump contains a temperature sensor and will recirculate the cold water back through the line until the set temperature is reached. When you hear the pump cut o , you can open the faucet

and have hot water at the location without any water wasted down the drain. Soon you will learn to ip the switch or push the button if you are preparing to use hot water, just as you ip the light switch when you enter the room. By the time you undress to shower or get the dinner ingredients out of the fridge, you will have hot water delivery.

Resist suggestions to install a motion sensor on these demand pumps. ink about how o en you go in the bathroom or kitchen and do not need hot water. If you have motion sensors installed, the pump will run every time, using energy even when you don’t need it. And don’t even think about installing a continuously operating circulating system, even if you intend to put it on a timer. Consider how many minutes you actually use hot water in the morning or evening compared to the number of hours you would set the timer to run constant circulation. Your water usage will vary day to day, even during the work week when you are on a more rigid schedule. And what about weekends? Are you going to set the timer to run from 7 am to 11 pm because you do not know when you might need hot water with everyone in and out of the house all day? is is very wasteful and expensive to do.

These on-demand hot water systems pay for themselves quickly when the dollars saved in both lower water bills and reduced water- heating costs are combined. e added convenience of not having to wait standing outside the shower watching water go down the drain is a great plus too. Compared to a constant circulation hot water system or a tankless water heater at each wet location (your only other options if you want hot water fast), these on-demand systems use far less energy since they only operate a few minutes per day instead of constantly. Convenience, water conservation and lower utility cost make this the best option to consider if you can- not design a central core system.

Publicadas por Edd a la/s 6:18 PM 12 comentarios

Central Core Plumbing Design

A large percentage of the cost of plumbing (both materials and labor) is due to long pipe runs. These same long pipe runs also mean more line full of water all the time, waiting to be wasted down the drain whenever you turn on the hot water tap. Shortening the plumbing runs saves initials costs of plumbing the home and saves water costs for the life of the home.

e most efficient plumbing design is to locate all of your wet areas (kitchen, baths and laundry) adjacent, or at least close, to each other and the water heater. If you are building more than a one- story home, the same is true for stacked plumbing locations, where upstairs bathrooms and laundry rooms are stacked directly above downstairs kitchen, laundry and powder room locations. is will deliver the best hot water service with the least amount of waste. Even if your home cannot be designed with a compact plumbing scheme, try to centrally locate the water heater at or near most of the wet areas.

Publicadas por Edd a la/s 6:11 PM 7 comentarios

Plumbing Design

With an exploding world population and shrinking supply of fresh water on the planet, many say (and we agree) that water resources are the next gold standard. In many areas of the country, potable water costs have doubled and tripled in just the last couple of years.10 To survive the coming supply and demand problems, we are going to have to find ways to get the most from every drop.

Plumbing piping systems provide both hot and cold water delivery, so design considerations provide the greatest bene t for indoor water conservation. It is important to remember that water stays in the plumbing lines all of the time. So every time you turn on the hot water, you will be wasting all the water already in the line waiting for that hot water to get to you from the water heater. is means you are paying for and wasting water that you never even use!

Efficient hot water delivery is achieved through a whole-system design approach, not just considering the type of water heater to be installed. Nothing can kill the efficiency of a high-efficiency water heater more quickly than a poorly designed distribution system. For efficient hot water delivery, you must have one of the following:

• Water heating equipment located within 20 feet (30 feet on 2-story homes) of all the wet locations in the house. is could be a tanked or a tankless unit.

• A manifold plumbing system (replaces the main water line with multiple smaller lines run to each fixture) with the manifold (split) centrally located within 10 feet of the water heater and no single branch line length exceeding 15 feet.

• A structured plumbing system (not a manifold system) consists of a main trunk line that services the entire house with smaller branch and twig lines to each wet area and fixtures, with an on-demand water recirculating system installed at the fixture(s) farthest from the water heater, and pump controls located at all wet locations along those long runs in the home.

Another critical element in achieving efficient hot water delivery is pipe insulation. No matter how efficient your design is in delivering hot water to the fixtures, we still see significant temperature drops during transmission or while water is sitting in the lines waiting for the next draw to occur. Also, when the hot water pipes are not insulated adequately, there are substantial heat losses from hot water running through pipes within the conditioned space of the home that add to the cooling load of the air conditioner. Insulation is cheap, easily installed and means hotter water at the tap for you and your family with a lower temperature setting on the water heater. Insulating three-quarter-inch pipe with three-quarter-inch insulation will triple the time before the water cools down; insulating half-inch pipe with half-inch insulation will double the cool-down period.

Publicadas por Edd a la/s 6:06 PM 2 comentarios

Etiquetas: Design

Framing Details

Framing details are necessary with almost any building structural system in use today. Straw bale buildings must have structural support members for load-bearing walls and roof assemblies, rammed earth buildings need structural framing for door and window openings, and of course, wood-framed homes need lots of details for structure and weatherproofing assemblies.

Design details provide templates for structural stability to keep the roof on the building (very important!), especially during high- risk events like snow storms or tornados. Wall assemblies also keep air infiltration manageable, help keep rain-driven water out of the wall assembly and allow moisture and water vapor that does get inside the wall to dry out. These details will vary depending on the climate location that the home is built in.

Your home plans should include framing details for every build- ing section, as well as detailed assembly specifications for walls, foundation, roof members and water flashing details for roofs, walls, windows and doors. The basic principles related to the building envelope are more influenced by design than the materials themselves, so they are best addressed here. By providing framing details in the drawings, framing contractors onsite are less likely to over-build assemblies, thinking that it is better to err on the side of adding more lumber than is necessary for structural integrity than not enough. Do not assume that the education level of a framing crew provides expertise in structural engineering or waterproofing. Instead, have your structural engineer or architect provide the framing and waterproofing details for wall, roof and floor assemblies (if you are not using engineered trusses or panelized assemblies). This will save you money because every material you purchase will be used as it was intended, instead of being mis- used, requiring you to purchase more materials either during construction or to repair poor workmanship later. O en construction drawings give the crew no clue as to how to waterproof and ash the critical openings and junctions in the house where most leaks will occur. A recent article in Builder Magazine8 found that about one-third of US homebuilders still don’t properly ash windows to prevent direct intrusion by rain. It stated that water leaks, especially around windows due to improper flashing, “routinely tops the list of builder callbacks.” It is imperative to the durability of your home that the flashing materials and their installation be detailed on the drawings.

Good building science is the perfect partner to green materials and design. Using the right materials to create the right building system for your climate will maximize the durability, healthfulness, comfort and efficiency of your new home. Make certain that your architect or engineer is on-board with your desire to maximize structural integrity while reducing waste and achieving a water- tight, durable and healthy structure.

If you have hired a custom builder for your project and are not working with the architect directly, you should make certain that the home plans that the builder is offering you have been designed according to the strategies outlined in this chapter to ensure that construction will be resource efficient. You should also ask the builder for written specifications for the basic building materials that are included in his quote for the home. Better to find out up- front if there are any surprises coming down that will throw you o budget.

Publicadas por Edd a la/s 6:03 PM 0 comentarios

Etiquetas: Building Tips

Wall Design

To optimize your design for resource efficiency, you will need to decide what type of structural system you will employ. As we discussed in the section on “Designing on Two-Foot Modules,” various building materials are manufactured in standardized sizes. In addition to dimensional lumber, this also applies to many alternative and natural building materials. Straw bale comes in standard bale dimensions, structural insulated panels (SIPs) and insulated concrete forms (ICFs) come in standard 4-foot wide and 8-, 9- or 10-foot heights, and autoclaved aerated blocks come in fixed block sizes. Knowing which type of system you will use will save you money on both materials and labor.

Publicadas por Edd a la/s 6:00 PM 2 comentarios

Building Stacked Stories

Foundation, wall and roof assemblies represent large portions of typical construction budgets. Stacked structures with more than one story can save considerably on material resources and therefore cost. Using in-line framing techniques the floor, wall and roof framing members are vertically aligned with one another so that loads are transferred directly downward, providing a sound structural assembly using less framing lumber. Also, since multi-story homes have a smaller footprint than single-story structures, they can be built at higher density, reducing land costs for affordable urban sites.

Publicadas por Edd a la/s 5:59 PM 1 comentarios

Etiquetas: Design

Building Designing for Two-Foot Modules

If you really want to optimize re- sources, create the least amount of waste and cut your base construction costs, design the building on two-foot increments. Most building materials come in two-foot incremental lengths or widths. Most lumber and millwork come in 8-, 10-, 12- and 16-foot lengths and sheathing, decking and drywall materials in 4 × 8, 4 × 9 or 4 × 10 sheets. Designing for two-foot modules is one aspect of Advanced Framing, which is a more efficient way to frame from both a materials use and energy use perspective (more on this in Chapter 4). So, overall exterior wall dimensions on your plans should be exact two-foot increments, and plate (ceiling) heights should be 8 feet, 9 feet or 10 feet (there is no reason to go over 10 feet) for optimal material efficiency and cost.

The same is true for interior room dimensions, but more with respect to finished flooring materials. Sheet goods (carpet and lino-leum) come in sheet widths of 6 feet, 12 feet or 15 feet, and tile and wood products typically come 25 square feet to a box. If you are not designing to those increments, you are going to waste a lot of materials. e worst case would be to design a room 12 feet and 7 inches wide or 15 feet and 2 inches long. If you are specifying sheet flooring, your installer will need to cut a 7-inch-wide piece to finish o the 12-foot standard roll width. Or for boxed goods, cut 2-inch strips to finish o that 15-foot full square on each run. Since some wood flooring is tongue-and-groove, once the two opposite edges of the piece are used to t the adjoining pieces, the rest of the square is waste as there are no usable edges remaining, or will require additional labor to router onsite.

Your building designer should hand you the finished plan sets, and you should easily see that overall building dimensions (not including exterior cladding) are measured in even 2-foot increments. is means that from corner to corner, sole plates, top plates, stud spacing, etc. all t within the standard measurements that wood framing is manufactured to, so no waste. is is the most efficient use of your money, as there is nothing worse than wasting it on material scraps in the dumpster!

Publicadas por Edd a la/s 5:54 PM 0 comentarios

Etiquetas: Design

Basic House Design

Typical homes built to current standards do not generally make it more than twenty years without needing some repairs. Many factors contribute to this, but certainly any complexity of the design,

creating potential for water leaks over time, is a significant influence. To reduce this risk, it’s best to keep the basic house design as simple as possible. Starting with the foundation, try to stay as close to a true rectangle as possible, avoiding projections in the footprint. Starting here, everything above the foundation then follows suit, you’ll have a simpler basic structural design, and a simpler roof design will follow. All of these efforts result in lowering the base bids for construction costs.

The shape factor concept used in designing post-tension foundations (SF=Foundation Perimeterº2/Foundation Area)6 indicates that changes in direction or projections require foundation engineering and reinforcements that not only add cost to the foundation, but also increase the incidence of failures. Beyond concerns for the foundation itself, all deviations from a basic rectangular de- sign add complications to structural assemblies and roof designs that are not only costly to build but again have greater potential for leaks. Costs increase not only because of the additional materials required to provide structural support, but also from increased labor that adds time and costs to construction schedules, impacting interim financing and construction costs. And it’s not just the money—chopped-up architectural designs waste natural resources, as they take much more materials to build the same basic square footage.

We also found a study that references shape factor in terms of the relationship between a building’s thermal envelope area and the volume of its conditioned space. From this perspective, buildings with higher shape factors, i.e., a larger area of exposed thermal envelope, use more energy than those of the same area but a smaller shape factor. This was especially true in cold climates due to an increased area of heat loss, and had less to no impact in climates as they progressed along a continuum to warmer.

Publicadas por Edd a la/s 5:50 PM 0 comentarios

Etiquetas: Design

Building Shading Devices

Wednesday, October 25, 2017Direct sun exposure on walls, especially west- facing walls (and south-facing walls in the summer) can significantly increase the loads on your cooling system—roof overhangs and porch roofs to the rescue! Many types of external shading de- vices that can keep heat from entering the building are o en recommended in lieu of prescribed low solar heat gain coefficient windows on southern exposures in passive solar design. These can include pergolas, awnings and patio covers.

Shading a window on the outside of the glass is twice as effective at reducing heat gain as doing so inside of the house. is is the best strategy for reducing cooling loads and lowering energy costs. Individual awning structures mounted directly above windows can provide more protection, being closer to the window, than an over-hang that is several feet above. Of course, the projection factor, or the ratio of the depth of the overhang or awning to the height above the sill of the window be- low it, will influence its effectiveness in shading all or portions of the window over the cycle of the sun’s path between the solstices. By using the projection factor formula, we can design the shading device to precisely control which months the sun is allowed to shine into these windows. Even in the north, you don’t need solar heat gain in July.

Never underestimate the benefits of any shading devices. As was previously mentioned, they also serve to protect exterior doors and windows during major rain or storm events. However, if external structural devices are not possible, trees can provide shade, either continually or seasonally. If your site does not have trees, neighboring buildings or other existing features can provide the desired shading on the east and west sides of your home.

Publicadas por Edd a la/s 11:37 AM 5 comentarios

Etiquetas: Green BuildIng

Building - Passive Solar Design

Wherever you live, you can embrace design strategies to further manage the sun’s heat loads on the structure. As we mentioned in Chapter 1, in the northern hemisphere the sun is always either in the southern sky or directly overhead. In North America, the sun rises at due east on the spring equinox, April 21, and fall equinox, September 21, and sets at due west on the same dates. On June 21, the summer solstice (the longest day of the year), the sun crosses at its highest path across the sky overhead, rising and setting well north of due east and west. Each day a er June 21, the sun’s path starts and ends further toward the south of due east and west and lower toward the southern horizon until it reaches its lowest path across the sky on December 21, the winter solstice (the shortest day of the year), and then the process reverses. Knowing the seasonal sun path across your site allows you to design to manage solar heat loads to your benefit. Take time to research your location’s latitude. e closer you are to the equator (like in the southern US), the more days you will need air conditioning rather than heating. You want to minimize the amount of solar heat gain on the structure, so, as mentioned in Chapter 1, you want the short walls of the house to face east and west; since these two walls have the least amount of wall area, they will absorb the least amount of solar heat into the home.

Interestingly enough, if you live in a predominantly cold climate area like the north (with more days needing heating than air conditioning), you should still design your home with the long walls of the rectangle running east and west.

Regardless of your latitude, you want the south-facing windows to be completely shaded at noon on June 21 and completely un- shaded at noon on December 21. e key here is the design of the overhangs. In this case they must keep the sun o the glass when the sun is high in summer and let it in when the sun is low on cold winter days. at means that we design to control the amount of heat gain through the south wall and windows. We can use ex- tended roof overhangs, covered porches and other shading devices (like awnings) to shield windows and walls on the south side of the house from the hot summer sun. is improves the cooling effects of passive ventilation strategies in the summer. These same windows on the south side of the home can provide passive heating of the living space when the sun’s path is lower in the sky in the winter. e result is that overhangs help to lower our mechanical heating and cooling costs.

As you can see in the drawing above, the lower the sun is in the sky and the shorter the overhang length, the further the sun penetrates into the house. e farther north you are, the lower the sun’s path across the sky, and the farther south you are, the higher in the sky it moves. is fact will affect the length of your overhangs and how you build to take advantage of or avoid solar heat gain in you home. All three of these things—length of the overhang, height of the overhang above the window, the angle of the sun in the sky— impact how much solar heat gain you will reap (or keep out, as the need may be).

Publicadas por Edd a la/s 11:30 AM 1 comentarios

Etiquetas: Green BuildIng

Building Stack Ventilation System

One of the basic principles we work with is that warm air rises. As this occurs, the area below is left under slightly lower pressure, so there is a suction effect. As the hot or warm air rises, windows located high on the opposite wall, or in an open upper-story area (like a stair-well, clerestory, cupola or monitor), can exhaust warm air out of the house while drawing cool breezes in. Any time we can use these passive ventilation strategies, we increase the velocity, and thus the effectiveness, of even the mildest breeze. Whole-house fans can intensify this effect. These devices are especially useful in areas where summer nights are relatively cool, exhausting warm air that builds up during the day and drawing in cool nighttime air for passive ventilation. If we can provide cool, comfortable air without having to use our mechanical systems, we save energy and money.

Publicadas por Edd a la/s 11:23 AM 1 comentarios

Etiquetas: Green BuildIng

Building Cross Ventilation System

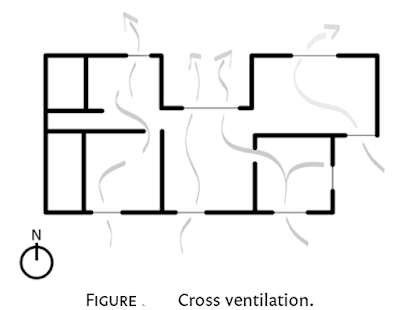

It is important to design your home with operable windows on the prevailing breeze side of the house (east or south sides, in Figure) and on the opposite side of the house for the purpose of supplying passive ventilation. e prevailing breeze creates pressure differences from one side of the house to the other. Strategically placed windows on the prevailing breeze side of the home and the opposite side work to draw the breeze through the living space. We can actually increase air ow through the space by opening more windows on the negative pressure northwest (downwind/leeward) side than on the positive pressure (southeast/ windward) side of the home. When wind currents travel through a constricted opening, the velocity increases (the Venturi effect). e Bernoulli principle determines that as the air speeds up, its pressure drops, causing it to create suction and drawing in even more air.

The same principle can be applied to the architectural layout of the structure itself, using a vernacular breezeway or dogtrot design to channel breezes into the living space. To increase the breeze’s effective cooling, the alignment of the building sections can be o set at an angle. In this way, we can use smaller windows or openings on the windward side of the dogtrot and larger windows or openings in the dogtrot on the leeward side to pull air through the structure. Windows on the side walls of the dogtrot are used to channel that increased volume of air into the living space of each building.

Publicadas por Edd a la/s 11:17 AM 1 comentarios

Etiquetas: Green BuildIng

Building Passive Ventilation System

Repeat again: ventilation. We tend to believe that all windows should be operable. Regardless of where you live, there are times of the day and times of the year when the outside temperature and humidity are comfortable. Fresh air can provide numerous health benefits, and the sounds and smells allow us to be a little closer to nature, even as we stay inside our sheltered home.

We talked about the importance of determining the direction of prevailing breezes and selecting a building site that could take advantage of passive ventilation strategies. These strategies should be a part of every good green home design. But for those breezes to really provide cooling for the home, the design must incorporate elements to promote air circulation through the building.

Windows, depending on location, can be used for cross ventilation, circulating natural breezes throughout the home, and stack ventilation, exhausting heat out through stairwells, monitors, cupolas or upstairs rooms. However, prevailing winds can be impeded by a number of factors, including adjacent structures and topography that either block the air ow or change its direction at window level. But if we can get above the obstruction, we can use our roof design as a scoop to channel the wind back down into the building. Wing walls can also accomplish this at ground level, if we can capture the breeze coming around the neighboring impediment and direct it back toward our other architectural features that are designed to capture it. Investing in these kinds of architectural details will pay o over the long run by reducing your mechanical cooling costs. We can also use natural ventilation strategies instead of running our air conditioners, thereby lowering our utility costs. Open windows can reduce our need to use mechanical ventilation appliances, like bath and kitchen exhaust vents. Opening the windows can also improve indoor air quality by exhausting stale, contaminated air, allowing us to temporarily shut o our mechanical fresh air systems. Opening the laundry room windows can provide a source for make-up air for the clothes dryer, preventing negative pressure that might bring in air from unwanted sources.

It is important to note, however, that operable windows should not be considered as a replacement for mechanical ventilation systems. ink about how o en you actually open your windows or how many days each year passive ventilation is a viable option for you. We will discuss indoor air quality and how to manage indoor air pollutants in your home. Mechanical ventilation is a necessary component of healthy indoor air quality. More than that, mechanical ventilation is a mandatory requirement in the 2012 International Residential Building and Energy codes. e paradigm is to build them tight and then ventilate them right! We will have more to say on the equipment to use and how to provide ventilation in the different climate zones in our country in Chapter 6. Yes, climate makes a big difference in how ventilation should be done.

Publicadas por Edd a la/s 11:14 AM 3 comentarios

Etiquetas: Green BuildIng

Roof Truss Design

If you are designing a home with a vented roof assembly, it is critical that the design include details that will allow the home to be constructed for the best thermal performance. Re- member, all homes should provide the best possible shelter from extreme weather conditions, but a green home should strive to achieve this by using good applied building science, better building methods and sound, passive design strategies. These efforts result in a durable, high-performance home that will continue to provide operational cost savings throughout its lifetime.

Building better requires us to look at how effectively traditional building practices have performed and whether we can improve upon those practices. Roof truss design is a good example of this. In traditional wood truss design, the roof rafters sit right on the ceiling joist, so there is not room to take full-depth insulation all the way out to the edge. is means that we end up with a fairly large gap between the end of the ceiling insulation and the top of the wall insulation, along the so t line. In a traditional wood-framed home, this is one of the most commonly missed areas of insulation, and since hot air rises, it provides a good escape route for heat to move outward from the conditioned space to the outdoors in the winter. In cold climates, the ceiling gets cold in this area, causing water condensation that leads to mold growth.

A better way to design trusses is with energy trusses or raised heel trusses. Energy trusses or trusses designed to cantilever out over the top plate provide an opportunity to get the insulation out all the way over the top plate of the exterior wall assembly. If your goal is net zero energy, the improved design and thermal performance work together to reduce loads on mechanical systems, i.e., building energy use. e International Energy Conservation Code also recognizes the inherent energy performance bene ts of energy and cantilevered truss designs by allowing you to reduce the overall attic insulation level if they are used.

Publicadas por Edd a la/s 10:49 AM 5 comentarios

Etiquetas: Rooft

Building - Next, look for natural drainage

Next, look for natural drainage patterns when investigating potential building sites. If you take a close look at the topographical map of the building sites below, some of the lots have low spots in the middle, probably about where a house would sit. Having water coming downhill toward your home’s foundation from all directions, even with the slightest slope, is not the preferred drainage plan and can lead to lots of costly problems in the future. If this is your situation, it will require designing alternative drainage routes and installing stormwater management controls.

We’ll discuss the importance of managing storm- water onsite. For now you just need to make certain that you are selecting a building site where it will be possible to establish positive water drainage away from your foundation. Verify that the site does not have flooding or access issues, or is not in a valley shaped like a bowl, making it impossible to manage stormwater drainage, or at the least, very expensive.

To take this concept a little further, though, it’s important to note that water also runs down a roof and down the wall and basement assemblies too. So in designing the home, make sure you establish a drainage pattern that provides a path to get water o and away from your home in rain and wind-driven storm events. inking ahead at this early point in the process will pay o many times over later in money saved on basement and foundation water management and on maintenance to repair water damage to your home.

Your site management plan should include effective temporary (i.e., during construction) erosion controls and stormwater management. You don’t want to lose your valuable topsoil that is ex- posed during the construction of the home. Silt fencing has long been recognized by building codes for meeting temporary erosion control standards, but other more natural materials work as well. Many green builders use straw bales to line the lot.

Publicadas por Edd a la/s 10:44 AM 0 comentarios

Etiquetas: Drains

Selecting a site that has good solar orientation

Selecting a site that has good solar orientation is one of the best strategies to lower your home’s operating costs. To determine the best way to orient your house based on this sun path, you need to figure out where you are on the planet. In the northern hemisphere, the sun is never in the northern sky, and it is either high in the sky (in the summer) or low toward the southern horizon (in the winter).

We’ll take a rectangular box design to illustrate the best design for passive solar benefits. To achieve the best orientation of your home on the site, you’ll need to determine the sun path across the site, from east to west. Once you have charted the sun paths, you will need to determine if it is possible to design the home on the site with the long walls of the rectangle running east to west (“east- west axis”).

It is important to recognize that the correct orientation of your house isn’t limited to which side of it faces the street. Which walls are the long or short walls will depend on how you design the home for the site. is could mean the front is a long wall if your site is facing south, or if your lot faces west, it could mean that the side wall facing south is now the focal point of a courtyard. Or maybe the house faces north and the back patio has large overhangs that serve as a passive solar feature. But if the site is on the north slope of a hill, having good solar orientation for your home is going to be a concern. e point is to make the best use of your site by designing for it.

Publicadas por Edd a la/s 10:40 AM 1 comentarios

Etiquetas: Building Tips